Up until the early 2000's the design and printing of company annual report and accounts was VERY big business. In the burgeoning design market of the 1980's and 90's There were many design companies which specialised in just annual reports (the likes of Michael Peter, Bamber Forsyth, Benjamin Rowntree, Radley Yeldar etc) and printers who would specialise in printing them such as Greenaway Harrison, Litho-Tech, Oakley Press, White Dove etc.

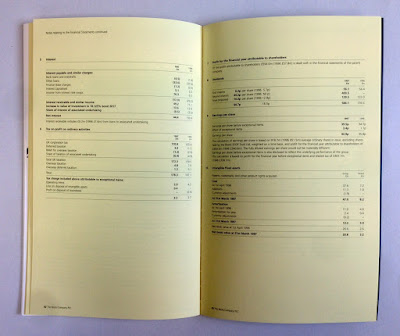

Back in those dim and distant days, it was very common for Annual Reports to be divided into the Report - printed on a white paper, printed in four colour process (with photographs!) and the Accounts section - printed on a coloured paper ...and this job follows that pattern.

This is the Report and Accounts for the Boots Company, the group of companies based on the Nottingham chemists founded in 1849 by John Boot. Back in 1997 they were a PLC in the FTSE 100, however ten years ago they were bought by a private equity firm based in Switzerland. The design is by Addison and the printer was Litho-Tech.

This is the Report and Accounts for the Boots Company, the group of companies based on the Nottingham chemists founded in 1849 by John Boot. Back in 1997 they were a PLC in the FTSE 100, however ten years ago they were bought by a private equity firm based in Switzerland. The design is by Addison and the printer was Litho-Tech.The size of the report is 297x180mm, portrait. It has a 4pp cover, which is printed in a blue and is matt laminated.

Below you can see the split between the two sections.

According to my notes, the 36pp front 'report' section was printed on Zanders Megamatt 150gsm, printed in CMYK, possibly with a special and a 'spot gloss machine varnish' which was a highly desirable effect back in those days.

The 44pp 'accounts' section is where I came in! I was briefed by Karen Blades, Production Manager at Addison to provide a bespoke paper to what was described as a 'post it note yellow' shade, which as you can see from the result below, we managed to achieve.

|

| Click on images to enlarge |

https://justinsamazingworldatfennerpaper.blogspot.co.uk/2015/10/what-is-mill-making.html

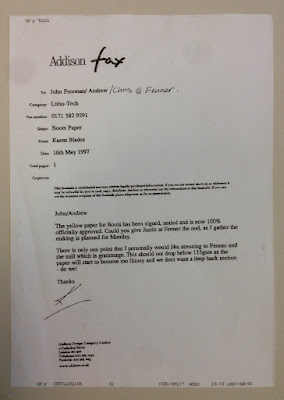

In this instance, the mill agreed to make a 2 tonne trial so a small group went to the mill to see the paper as it was being made. This was pretty unusual even in those days! ...so I visited the Guardbridge mill accompanied by Karen Blades from Addison and Derek Adnitt and Les Baker from Litho-Tech printers. As a result we were able to show the client EXACTLY the paper they were getting.

After that trial, Boots were shown the paper, it was approved and then the mill manufactured the remainder of the paper.

- and back in those days everything was done by fax and fortunately I still have the fax in my archive with the approval...

|

| Click on images to enlarge |

Karen Blades now works at Print Source UK and still spends her time producing quality annual reports!

...a real trip down memory lane!

http://www.boots.com/

https://www.addison-group.net/

Posted by Justin Hobson 01.09.2017

No comments:

Post a Comment

Thanks for your comment! If I like it, I'll add it on. Cheers J