What is ...Number 3

Regular followers of this blog will know that in the middle of the month, I publish a "What is ....? post. The article covers various aspects of paper, printing and finishing in greater depth. However, many of these subjects are complex, so these posts are only intended to be a brief introduction to the topic.

What is ...Singer sewing?

Singer sewing is a binding method which uses thread. Generally it is done in a highly visible way and often uses a coloured thread to highlight the binding.

The machinery used by the bindery for this is, in fact, very similar to a domestic sewing machine and like all the best sewing machines that our Mum's have, it's made by Singer! (other makes are available). It works in exactly the same way as a conventional sewing machine for cloth but with an industrial motor and a high strength needle. Researching this article, I understand that some machines will sew up to 10mm of paper - that's quite a lot!

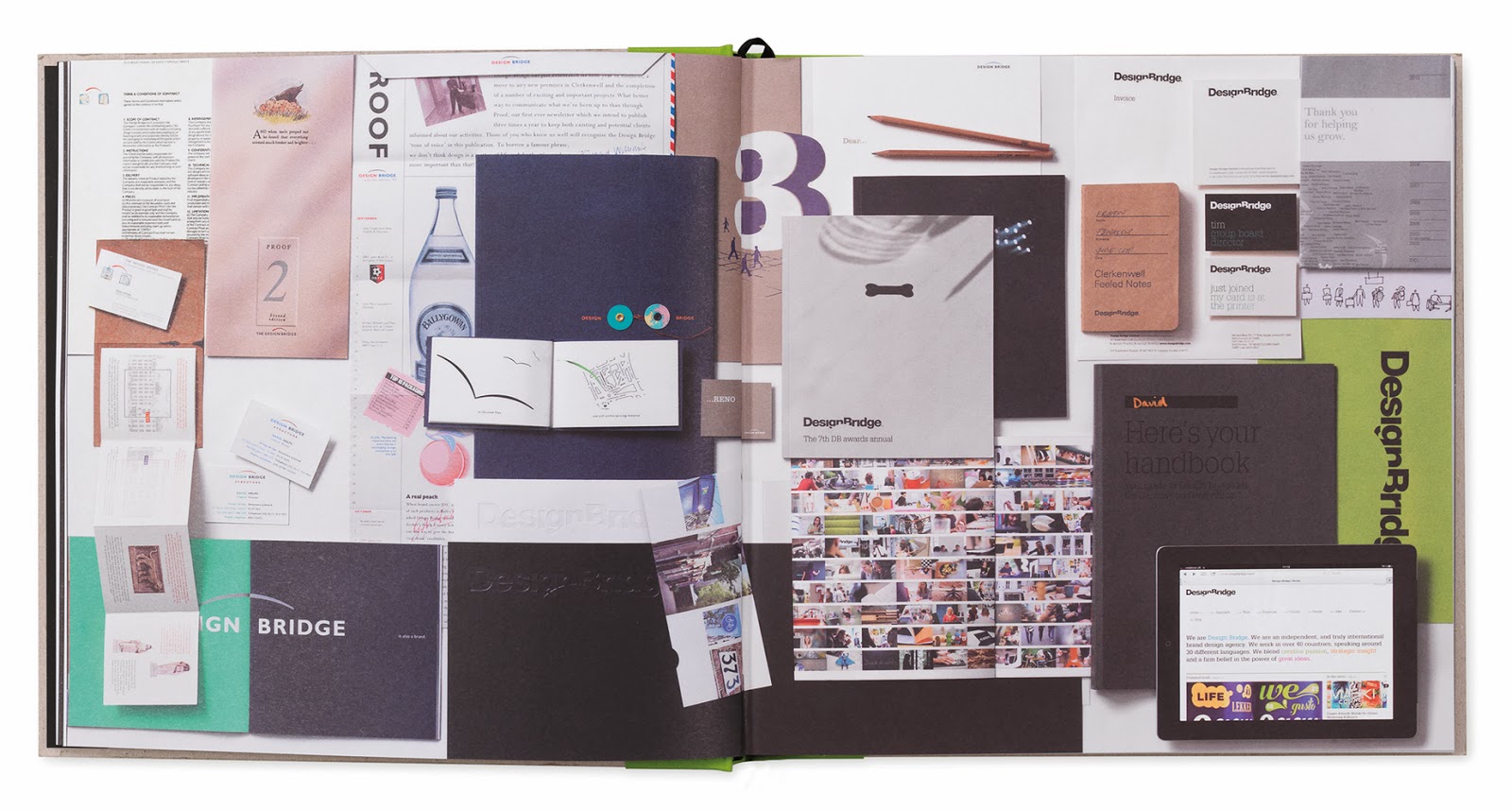

Singer sewn projects have appeared often enough on this blog that I can easily illustrate it with these existing projects. The below picture shows a singer sewn publication:

There are however two distinct types of singer sewing and unfortunately in the mysterious world of print terminology, it's not always clear what people mean or what terms they are using, so I shall try an de-mystify!

The project below has been finished over a "saddle", in the same way that a "wire stitched" or "saddle stitched" job is finished (or as most people out of the industry would call it - stapled with metal staples). The term saddle is used because it sits astride a saddle in the same way as a saddle sits on a horse. This then allows the machine to guide the thread or wire, accurately through the folded spine. As with wire stitching, there is a limit to how thick you can bind, because you have to consider the fold.

However, you can also set it up so that the thread penetrates the whole thickness of the publication and is therefore visible on both the outside front cover and outside back cover. Normally the sewing is set in about 5-10mm in from the spine, as in the picture below. Often this is done with loose sheets of paper (as below) and there is no folded paper on the spine and the edge of the paper is visible on the spine.

Both examples above are accurately described as singer sewn. However, I prefer to call the above example (that goes through the whole book) "Side Sewing" as I think it is more descriptive but it is also referred to as "Stab Sewn". Like most terminology in printing, it is as much useful as it is a hindrance. Most important of all is to communicate clearly what is required, either in words, drawing or picture.

I am often asked if this type of binding is a machine process or a hand process. The best way to describe it, is a "hand operated machine process" as unlike a truly mechanised process, the book has to be manually handled through the machine .

Another feature of the binding, is that you can leave the thread hanging, rather than having it cut flush in line with the edge of the book. This can work beautifully with the design, as with the project below:

Not all binderies have a machine that can do this type of binding but there are a fair few finishers around the country that can handle this type of work. If you want a suggestion, just ask me...

Posted by Justin Hobson 18.03.2014

Further to my post about IPEX (International Printing Exhibition) last week, it may interest you to know that this week I find that I am now at the exhibition all week!

Further to my post about IPEX (International Printing Exhibition) last week, it may interest you to know that this week I find that I am now at the exhibition all week!