What is ...Number 16

Regular followers of this blog will know that in the middle of the month, I publish a "What is ....? post. The article covers various aspects of paper, printing and finishing in greater depth. However, many of these subjects are complex, so these posts are only intended to be a brief introduction to the topic.

|

| Click on image to enlarge all images |

Back 'in the day' Dutch Greyboard just came from Holland and was a superior product to the UK manufactured chipboards but nowadays the 'dutch' has been dropped and 'Greyboard' is the generic term used in the UK industry.

Although all paper and board is sold by price which is calculated by weight (grams per square meter - gsm) Greyboard and other boards are manufactured to a thickness or caliper, which is measured in microns, often referred to as mics or by the symbol µ (classical Greek for the letter M)

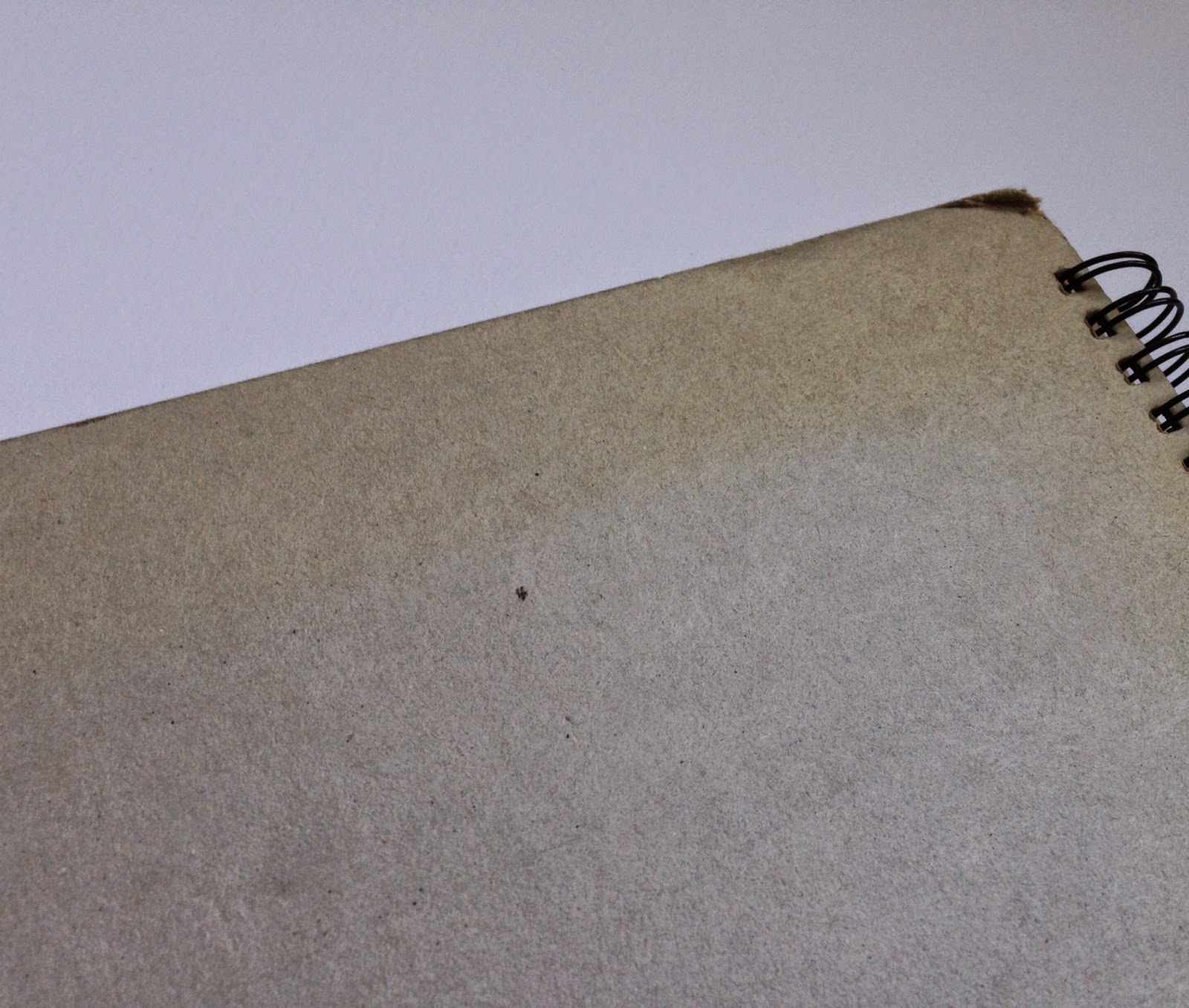

Many people want to use greyboard because it has a 'raw' unfinished appearance. It's also extremely cheap compared with virtually any other heavyweight/thick product and it is environmentally friendly, being made using the lowest grade recycled fibres (pictured left).

Greyboard can be used very effectively in a variety of ways including business cards, postcards and as covers, such as this RCA catalogue from 2004 - in this instance, it has been hot foil blocked in a clear foil with cloth tape running along the spine.

As you can see this is a great result, however, be warned, there are a few issues about the product which is important to realise and I'm about to reveal what they are...

Firstly, the shade (colour) and surface is not consistent both from batch to batch and mill to mill. Below is an image of 1000 micron greyboard which I recently received from a board mill. The one on the left was the sample I received and the one on the right was a piece taken from the actual order we received - quite different in both shade and surface BUT they both measure 1000microns thick and that is about the only criteria that this product is made to.

|

| click on image to enlarge |

In a high volume, cost driven business, using a low quality 100% recycled fibre this is to be expected and is totally acceptable - so don't expect to send it back or be unhappy if it isn't quite the same as the sample you received!

Above is a set of samples of different weights from a supplier - the only thing you can say regarding consistency, is that there isn't any!

|

| Click on image to enlarge |

Generally speaking, the weight range of greyboard is from around 300gsm/500micron and goes up to around 1500gsm/3000micron, but as I mentioned previously the importance with this as a product, is it's thickness as you see in the image on the right, showing boards up to 3mm thick (3000microns)

Greyboard is not guaranteed for printing, certainly not offset litho printing. That is not to say that printers won't or can't print it but many printers are reluctant, as the manufacturing mills don't make any guarantee for the printability of the product and if it was to go wrong/cause a problem in the printing press, the mill would not cover any losses due to the product. The same can be said for hot foil blocking, it may work, but it may not and the risk/responsibility is all with the foiler and the designer.

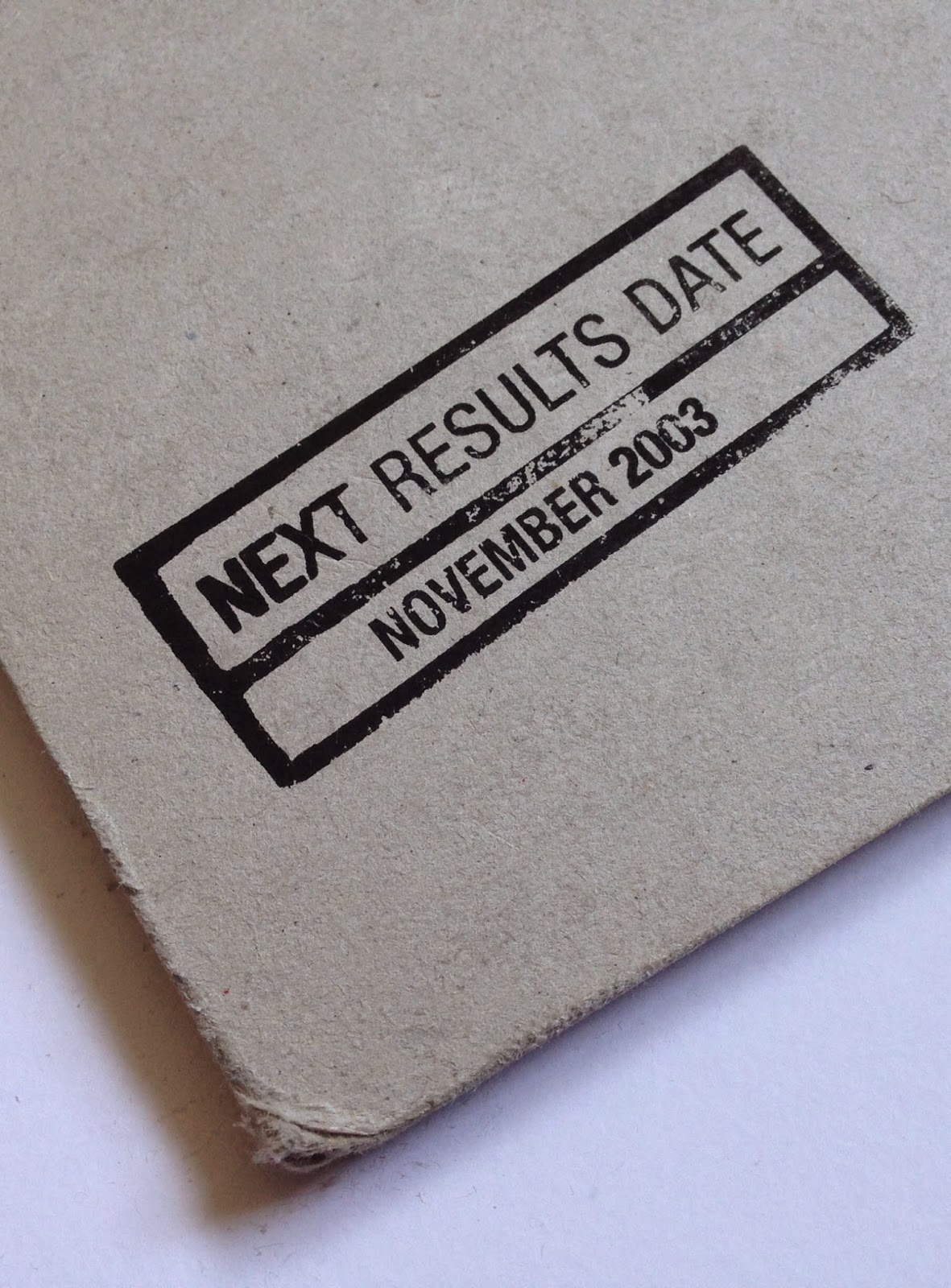

Another issue, is that because it is made with the lowest grade of waste, it is not guaranteed to be acid free, and can (not will) discolour and fade, as you can see in the picture below.

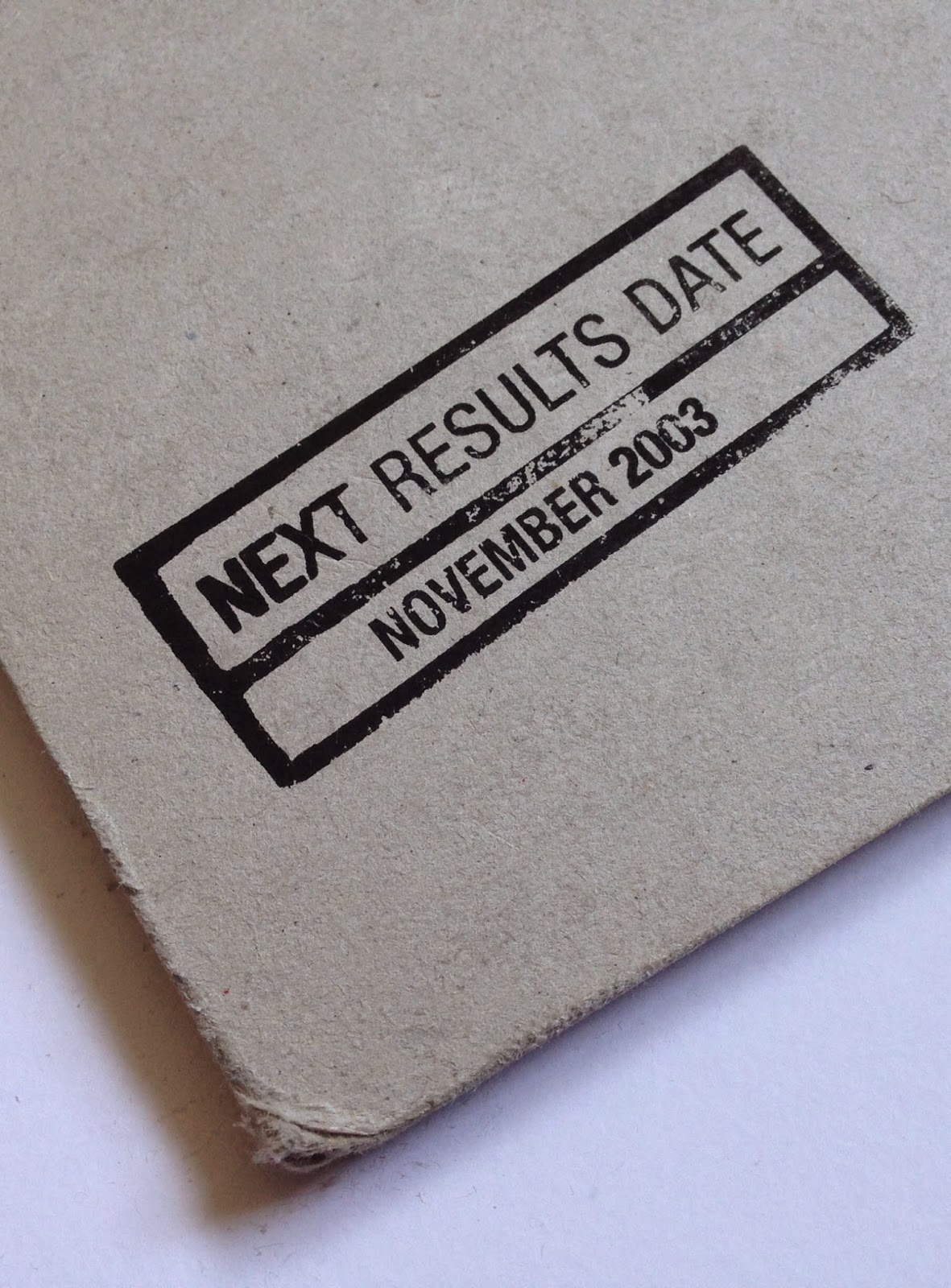

Because of it's unrefined, soft, fiberous nature, greyboard does not tend to wear well and will oftern "feather" along worn edges - this is where fibers come loose along a cut edge. As you can see from the back cover of the annual report below (Speedy Hire Annual Report 2003, designed by NB:Studio for MerchantCantos) it does not wear well.

|

| Click on image to enlarge |

It might seem like I'm giving a doom and gloom report about this type of product and only writing negative things! Greyboard is a useful, cheap product and can be used in innovative, exciting and different ways and yes, people can revel in it's grungy appearance! BUT, many people (clients in particular) expect manufactured products to have a consistency (and almost a perfection!) to them, which this product just doesn't have. All I'm trying to do is draw people's attention to some of the product's shortcomings.

Another question I get asked is why is some greyboard called unpasted and some called pasted. Basically this refers to the manufacturing process. Unpasted greyboard is produced in a single ply and tends to be rougher, whereas pasted greyboard is produced in layers on the board machine and is almost always smoother - it is NOT duplexed like a paper can be, to make a thick board, it is produced on the board machine in multiple layers.

Like most areas of industry, there are many different grades of product available - superior quality for bookbinding or photographic mounting for example.

For interest, here is a link to a greyboard manufacturer in the US, but they still call it Chipboard over there!

http://www.newmanpaperboard.com/#

Posted by Justin Hobson 17.04.2015

This is the private view invitation for an exhibition at the Crafts Council Gallery in London. The invitation is the the opening of an exhibition titled Heart of Glass, featuring work of the artists Jean-Michel Othoniel, Tony Oursler, Katy Schimert, Kiki Smith, Jan Vercruysse, Not Vital and Robin Winters.

This is the private view invitation for an exhibition at the Crafts Council Gallery in London. The invitation is the the opening of an exhibition titled Heart of Glass, featuring work of the artists Jean-Michel Othoniel, Tony Oursler, Katy Schimert, Kiki Smith, Jan Vercruysse, Not Vital and Robin Winters.